-

at

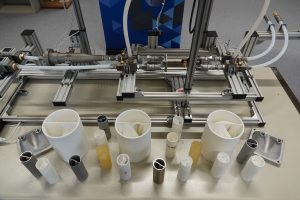

Automation Technology

Automation technology works at the interface between electronics, informatics, mechanical engineering and business. The challenge when automating technical processes is to produce an optimum mix between mostly conflicting aspects of time, cost, quality, resources and the environment. Here it is important to consider the whole system instead of optimising individual components independently from one another. Modular solutions are therefore becoming increasingly more important.

-

innoInnovation Management

Innovation Management

Turn a flash of genius, a brilliant idea into success! As essential success factors, new innovations are constantly needed in businesses in order to gain a competitive edge. The best idea however, can only become a successful innovation if customer needs and market changes are considered. Therefore, it is becoming increasingly important for companies to employ business engineers that have systematic innovation skills.

-

iwiInformation Technologies & Business Informatics

Information Technologies & Business Informatics

One thing is certain: There is a lack of business informaticians, yet the demand in business continues to grow. In an increasingly complex professional world, specialising in only one field is no longer advantageous. Therefore, business informatics is becoming more important as the link between business and informatics.

-

rwcFinancial Accounting & Management Accounting

Financial Accounting & Management Accounting

Business success and an efficient company organisation are not based on luck or coincidence, but on ideal strategic planning, leadership skills and state-of-the-art knowledge about processes in management accounting and business administration. The Degree Programme in Financial Accounting & Management Accounting offers cutting-edge and practice-oriented training based on the newest developments in the industry, equips you with the perfect tool kit to lead a company to success and move to top positions in international groups.

-

msMarketing & Sales

Marketing & Sales

A well functioning cooperation between marketing and sales is the key to attracting, convincing and retaining customers along the customer journey. A close and cooperative exchange between these two disciplines and the development of common goals therefore contributes significantly to the success of a company. Through the mixture of theory and practice, our students develop all the skills and competences that are needed in digital marketing and sales and are thus well prepared for the day to day work in these disciplines.